Top 10 Benefits of Using an Automatic Tool Changer Robot in Manufacturing

In today’s fast-paced manufacturing landscape, efficiency is crucial. The use of an automatic tool changer robot has emerged as a game changer. According to a report by the International Federation of Robotics, industrial robot sales increased by 12% in 2022, highlighting the growing trend towards automation. An automatic tool changer robot allows for quick tool exchanges, enhancing productivity in various operations.

Manufacturers benefit significantly from these robotic systems. They decrease downtime during tool changes, which can boost overall efficiency by up to 30%. Additionally, these robots improve precision in tasks, reducing errors associated with manual tool handling. However, the initial investment can be daunting, and some manufacturers may hesitate before adopting this technology.

Despite the challenges, the advantages are compelling. Increased flexibility in production processes allows companies to adapt to changing market demands. With the integration of automatic tool changer robots, businesses can remain competitive while navigating an ever-evolving industry landscape. The transition requires careful consideration, but the long-term benefits are evident.

Benefits of Enhanced Productivity with Automatic Tool Changer Robots

The manufacturing industry is experiencing a shift towards automation. Automatic tool changer robots are becoming essential tools on the factory floor. These robots streamline operations and boost productivity significantly. According to a report from McKinsey, automation can increase productivity by up to 30%. This is a compelling reason for manufacturers to invest in these technologies.

One major benefit of automatic tool changers is their ability to reduce downtime. Traditional machines often require manual tool changes, which can waste hours in production. With automated systems, the tool can be changed in seconds. Research indicates that reducing downtime by even a small percentage can lead to substantial gains in output. Companies can produce more parts in less time, thus meeting demand more effectively.

However, the integration of automatic tool change robots is not without challenges. Training staff to operate and maintain these systems can be complex. Moreover, initial investment costs can be high. It's crucial for manufacturers to assess whether the long-term gains justify these upfront expenses. While the data suggests strong benefits, not all companies may benefit equally from this technology.

Top 10 Benefits of Using an Automatic Tool Changer Robot in Manufacturing

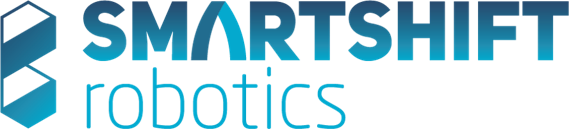

Improved Precision and Consistency in Manufacturing Processes

The integration of automatic tool changer robots in manufacturing has transformed the industry. Improved precision and consistency are at the forefront of this change. According to industry reports, manufacturers have experienced a 30% reduction in production errors since adopting these automation tools. Precision is vital in maintaining quality standards. Any deviation can lead to costly reworks.

Automation increases the uniformity of produced parts. This is notable in sectors such as automotive and electronics. Where every detail matters, a slight error can disrupt assembly lines. A tool changer robot can switch tools within seconds, ensuring machines operate at peak performance. This efficiency guarantees that products meet stringent specifications.

Tips: To achieve the most from automation, begin with training staff. Ensure they understand how to operate the robots effectively. Regular maintenance is also critical; it keeps the machines working efficiently and extends their lifespan. Reflecting on the challenges faced when integrating these robots can reveal areas for further improvement and innovation in processes.

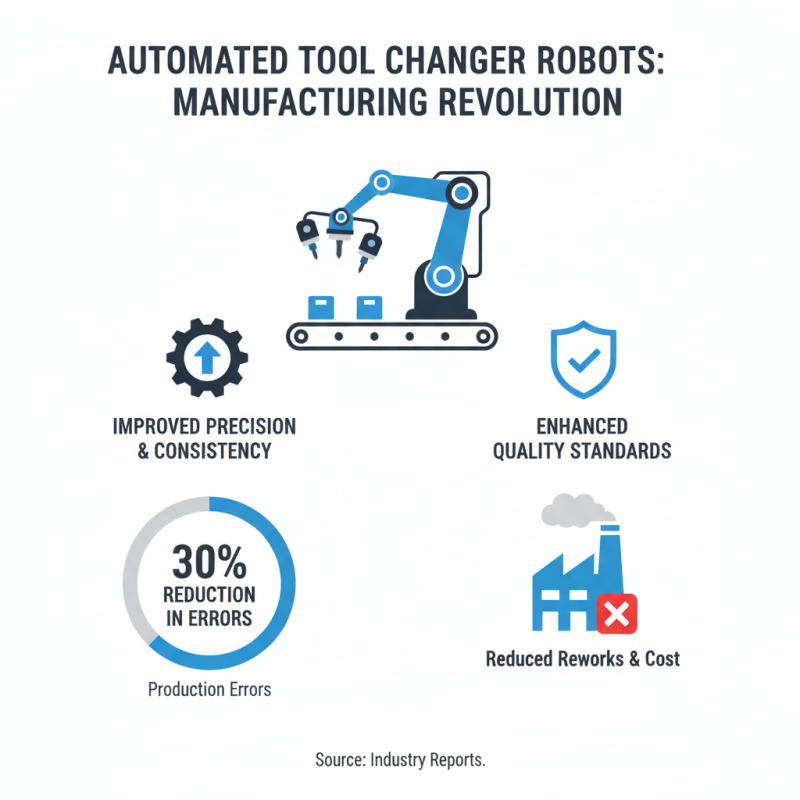

Reduction of Downtime Through Efficient Tool Switching

An automatic tool changer robot significantly reduces downtime in manufacturing. Quick tool switching is crucial for maintaining productivity. With traditional setups, switching tools can take several minutes. This delay accumulates, impacting overall efficiency. Automatic systems allow for seamless transitions. The change happens in seconds, keeping machines running longer.

This technology brings flexibility to production lines. Robots can switch between various tools based on tasks. This adaptability can lead to varied manufacturing processes without human intervention. However, challenges exist. Calibration for different tools can be tricky. Operators need to regularly check the system for accuracy. Mistakes in tool changes can halt production and lead to errors in assembly. Therefore, it’s essential to continuously fine-tune these systems.

Cost Savings from Increased Operational Efficiency

In modern manufacturing, automatic tool changer robots bring substantial cost savings. A recent report from IndustryWeek noted that automating tool changes can improve operational efficiency by up to 30%. This means faster production cycles and reduced downtime. When machines switch tools automatically, production lines run smoother and more consistently.

Moreover, labor costs decrease with automation. Studies show that businesses can save roughly 20% on labor costs by using robotic systems. These robots handle repetitive tasks, allowing human workers to focus on more complex issues. This shift can enhance overall productivity and flexibility in manufacturing processes. However, it's crucial to note that initial investments in these technologies can be steep. Companies must assess their ROI carefully.

Despite these benefits, the transition to automated systems isn't without challenges. Some workers may struggle to adapt, leading to potential slowdowns initially. Training is necessary, yet it incurs additional costs. Therefore, while automatic tool changers can provide significant savings, companies must plan thoroughly before implementing these systems. Balancing innovation with workforce readiness is vital for long-term success.

Greater Flexibility in Handling Diverse Manufacturing Tasks

In the manufacturing sector, flexibility is crucial. An automatic tool changer robot provides just that. It can handle various tasks without needing extensive downtime. This adaptability allows manufacturers to switch between processes quickly. For instance, a single robot can shift from welding to painting within minutes. This reduces wasted time and boosts productivity.

Moreover, having a multi-functional robot helps in reducing labor costs. It minimizes the need for multiple machines. With fewer machines to maintain, overhead costs decrease as well. However, implementing such systems can come with challenges. This includes initial setup costs and the learning curve for workers. Not all employees may be ready to embrace these changes.

Despite these hurdles, the benefits are significant. Greater flexibility can lead to enhanced customization options. Manufacturers can respond swiftly to market demands. Yet, one must be cautious. The reliance on technology can risk creating skill gaps among workers. Balancing automation with human skills is essential for sustainable growth.