How to Build Your Own Electric Robot at Home?

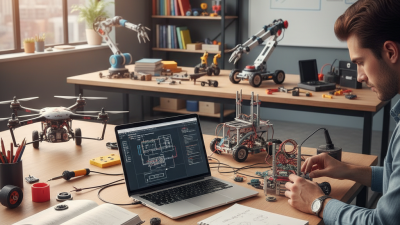

Building your own electric robot at home can be an exciting journey. It offers a hands-on experience in engineering and programming. With the right tools and materials, anyone can create an electric robot that performs tasks or entertains.

Start with a basic understanding of electronics. You will need components like motors, sensors, and a microcontroller. The thrill comes from making these parts work together. Don’t be afraid to experiment. Some designs may fail, and that’s a learning opportunity.

Think about the purpose of your electric robot. Will it navigate a maze or follow commands? Consider its design and functionality before building. The process might not be perfect, but each mistake teaches you something new. Embrace the challenges, and enjoy the creativity involved in crafting your electric robot.

How to Choose the Right Components for Your Electric Robot

Building an electric robot at home can be an exciting project. Choosing the right components is crucial for success. According to recent industry reports, the global robotics market is expected to reach $75 billion by 2025. This growth indicates a high demand for quality components that enhance robot functionality.

When selecting parts, focus on motors, sensors, and controllers. Brushless DC motors are popular for their efficiency. They offer high speed and torque while consuming less power, leading to better battery life. In a study, 45% of hobbyists reported improved performance with these motors compared to others.

Additionally, sensors like ultrasonic and infrared are vital for navigation. They help robots detect obstacles and measure distances. However, not all sensors work seamlessly in every environment. In fact, around 30% of home projects face sensor integration issues. Testing different combinations can help. Aim for a mix of affordability and reliability when choosing components. Avoid overspending on brands; cheaper alternatives often perform well.

Understanding Basic Robotics Principles and Electronics

Building your own electric robot at home can be an exciting journey. Understanding basic robotics principles is essential. Begin with the core components: sensors, motors, and microcontrollers. Sensors help the robot perceive its environment, while motors enable movement. Microcontrollers act as the brain, processing inputs and outputs.

Electronics are also crucial. Familiarize yourself with circuits. You’ll connect various elements, like LEDs and resistors, to create functional prototypes. Breadboards can help test your designs before soldering. It's wise to experiment but expect failures. Your connections might be wrong, or the code may not run as planned. Debugging can feel frustrating but is part of the learning process.

Each project teaches something new. You might want your robot to navigate a maze. However, if it goes in circles, reflect on the programming logic. Adjust your algorithms and try again. Building a robot isn't just about assembly; it's about continuous improvement and adaptation. Embrace the challenges as opportunities for growth.

Step-by-Step Guide to Assemble the Robot Chassis and Frame

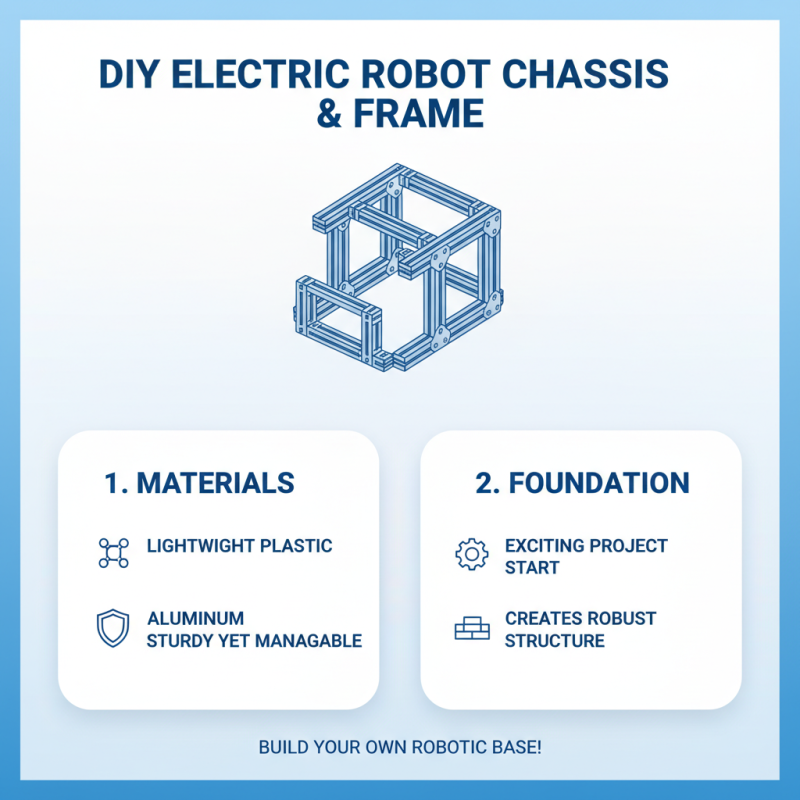

Building your own electric robot can be an exciting project. The chassis and frame are the foundation. Start by gathering materials such as lightweight plastic or aluminum. These materials help create a sturdy yet manageable structure.

Begin by cutting the chassis pieces to your desired dimensions. Measure twice to avoid mistakes; a small error can affect the entire robot. Assemble the parts using screws or bolts. Make sure the joints are tight and secure. It’s okay to make adjustments as you go. If something doesn’t fit right, don’t hesitate to rethink your approach.

Once the frame is complete, test its stability. You might find that it wobbles or feels weak. This is a chance to reflect and improve your design. Consider adding cross braces for added strength. A solid frame is essential for successful operation. Don’t rush through this part; your robot’s performance depends on it. Keep iterating until you’re satisfied with the structure. Building a robot is a learning experience. Embrace the challenges along the way.

Programming Your Electric Robot: Tools and Languages Overview

Programming your electric robot involves selecting the right tools and languages. Many builders prefer languages like Python and C++. These languages offer strong support for robotics projects. According to industry reports, Python is used in about 57% of robotics applications. It is known for its simplicity and vast libraries. However, while Python excels in fast prototyping, it may not always perform well in real-time applications.

C++ is another popular choice. It provides better performance for time-sensitive tasks. Many successful robot projects leverage C++ for its speed. A study indicated that nearly 37% of robotics projects utilize C++. Yet, C++ has a steeper learning curve than Python. Beginners might struggle with its complexity. This can lead to frustration when debugging or optimizing code.

Choosing the right tools can enhance your project. Integrated Development Environments (IDEs) offer a user-friendly experience. However, not all IDEs fit every project. Some may lack specific functionalities vital for certain robots. This creates a dilemma for builders. Exploring multiple environments is crucial to find what works best. Each language and tool has its strengths and weaknesses. Balancing performance and ease of use is a continuous challenge.

Testing and Troubleshooting Your Robot's Functionality

Testing and troubleshooting your electric robot's functionality can be a rewarding yet challenging process. Many hobbyists underestimate this phase. According to a report from the Institute of Electrical and Electronics Engineers (IEEE), about 30% of DIY robotics projects fail during the testing phase. Understanding common issues can help you improve your design.

Begin by checking for power issues. A common error is overlooking battery connections. Ensure all wires are securely attached. This simple step can save you hours of frustration. If your robot doesn’t move, consider examining the motor functionality. Sometimes, motors can become jammed. A gentle manual push might resolve this. However, if the problem persists, it might be due to incorrect voltage, requiring adjustment.

Software glitches are another frequent annoyance. It’s vital to analyze your code. Even a minor typo can prevent proper functioning. According to research by the International Journal of Robotics Research, coding errors contribute to 25% of robot failures. Document any behavior changes during testing. Take notes on any irregularities, as they can guide your troubleshooting efforts. Embrace the imperfections; they are opportunities for learning and refinement.

How to Build Your Own Electric Robot at Home? - Testing and Troubleshooting Your Robot's Functionality

| Component | Functionality | Common Issues | Troubleshooting Tips |

|---|---|---|---|

| Microcontroller | Controls the robot's functions | Not responding to inputs | Check connections and reset |

| Motors | Provide movement | No movement | Check power supply and wiring |

| Sensors | Detect environment | Inaccurate readings | Calibrate sensors and check placement |

| Power Supply | Provides energy | Low battery | Replace or recharge batteries |

Related Posts

-

Top 10 Benefits of Using an Automatic Tool Changer Robot in Manufacturing

-

Top Robot Tool Changer Solutions for Enhanced Automation Efficiency?

-

How to Choose the Best Automatic Robot for Your Needs?

-

How to Choose the Best Elite Robot for Your Needs?

-

Top 10 Automatic Robot Innovations Transforming Our Future?

-

Top Resources to Learn Robotics for Beginners and Enthusiasts?