Top Robot Tool Changer Solutions for Enhanced Automation Efficiency?

In the realm of industrial automation, the "robot tool changer" has become a pivotal innovation. Experts like Dr. Emma Chen, a leader in robotic systems, emphasize its significance, stating, "A good tool changer can drastically enhance a robot's versatility." This statement encapsulates the crucial role that efficient tool changers play in modern manufacturing.

As businesses seek to optimize production rates, the demand for robust robot tool changers grows. High-performance tool changers minimize downtime, allowing for seamless transitions between tasks. They enable robots to adapt swiftly to various operations, reducing the need for human intervention. This flexibility not only increases throughput but also addresses the challenges of labor shortages.

However, not all robot tool changers are created equal. Companies must carefully assess compatibility and integration with existing systems. Investing in a subpar tool changer may lead to inefficiencies and increased costs. As the robotics industry continues to evolve, a focused approach to selecting the right robot tool changer becomes essential for sustaining competitive advantage.

Top Robot Tool Changer Solutions in the Automation Industry Today

In the automation industry today, robot tool changers are vital for improving efficiency. They allow automated systems to switch between different tools rapidly. This flexibility is essential in various applications, such as assembly lines and packaging processes. The ability to adapt quickly can reduce downtime and enhance productivity.

However, selecting the right tool changer is crucial. Not all solutions fit every need. The size, weight, and type of tools are significant factors. A mismatch can lead to inefficiencies or even equipment damage. Not every system handles payloads effectively. Some may lack the precision required in intricate tasks. Ensuring compatibility with existing robotic arms is also necessary.

Integration challenges can arise during implementation. Proper alignment and calibration are pivotal for optimal performance. Ignoring this can cause miscommunication between components. While advancements continue to emerge, some tools fall short of expectations. Continuous improvement is essential. Regular assessments help identify gaps and unaddressed issues. Continuous adaptation will define successful automation in the future.

Top Robot Tool Changer Solutions for Enhanced Automation Efficiency

Key Features of Effective Robot Tool Changer Technologies

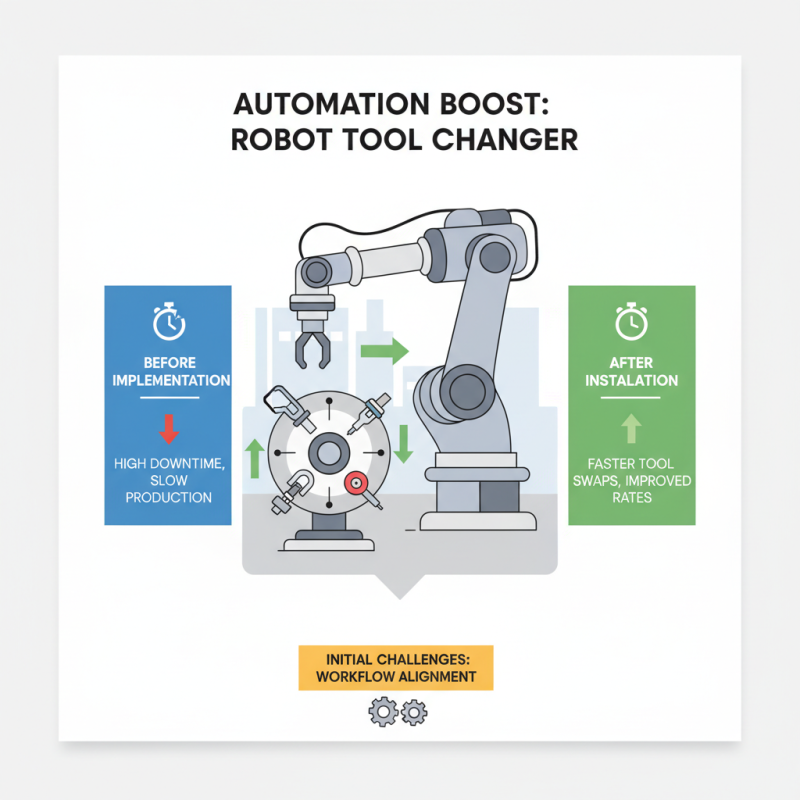

In the modern automation landscape, tool changers have become essential for robotic systems. Effective robot tool changers can significantly enhance productivity. They offer quick exchanges between different tools, enabling robots to handle various tasks. According to industry reports, companies using advanced tool changers have seen up to a 30% increase in operational efficiency.

One key feature of effective tool changers is their precision. High-quality changers minimize the risk of misalignment. This enhances the accuracy of operations, reducing wastage. For example, a misaligned tool can lead to incorrect placements, resulting in expensive rework. Additionally, an increasing number of manufacturers emphasize durability. Tool changers made from robust materials can withstand rigorous use, which is critical in high-cycle environments.

Flexibility is another important aspect. An ideal tool changer should easily accommodate different payloads and tools. This adaptability allows companies to quickly pivot their production lines. However, not all solutions are created equal. Some may lack the speed and customization options needed for specific tasks. This limitation can slow down the automation process. As industries evolve, ensuring that robotic systems have the right tool changers is vital to maintaining a competitive edge.

Top Robot Tool Changer Solutions for Enhanced Automation Efficiency

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Quick Change Mechanism | Allows for rapid tool swapping without manual intervention. | Increases operational efficiency and reduces downtime. | Manufacturing, assembly lines, and packaging. |

| Robust Design | Durable materials that withstand harsh industrial environments. | Minimizes maintenance costs and extends lifespan. | Heavy manufacturing and automotive industries. |

| Compatibility | Designed to work with various robot types and tools. | Flexible integration into existing systems. | Diversified manufacturing processes. |

| Sensor Integration | Incorporates sensors for precision and safety during operation. | Enhances reliability and reduces risk of errors. | Quality control and hazardous environments. |

| Compact Design | Space-saving construction for tight workspaces. | Optimizes space utilization in production areas. | Robotics' assembly and small parts handling. |

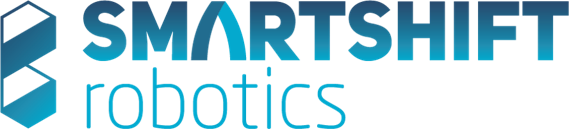

Market Trends: Growth of Robot Tool Changers in Automation Applications

The demand for robot tool changers is surging. According to a recent industry report, the market for robot tool changers is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is attributed to increased automation in manufacturing and logistics sectors.

Robot tool changers enhance flexibility. They allow robots to switch between various tools quickly. This feature boosts operational efficiency. Applications span diverse fields, from automotive to electronics. A key challenge is ensuring compatibility with different robot types. Many businesses face the dilemma of choosing the right tool changers for their specific needs.

**Tip:** Always assess your current automation level before investing. Understand which tools are essential for your processes. This helps in selecting the most suitable robot changers.

Recent data shows that over 50% of manufacturers see robot tool changers as pivotal for future growth. However, there are concerns about the high cost of these solutions. Companies often struggle with budgeting. The investment must align with projected efficiency gains. Aim for a balance between expense and operational enhancement.

**Tip:** Consider pilot projects before full-scale implementation. Testing small can provide valuable insights into the effectiveness of tool changers. This way, you can refine your approach.

Case Studies: Successful Implementations of Robot Tool Changers

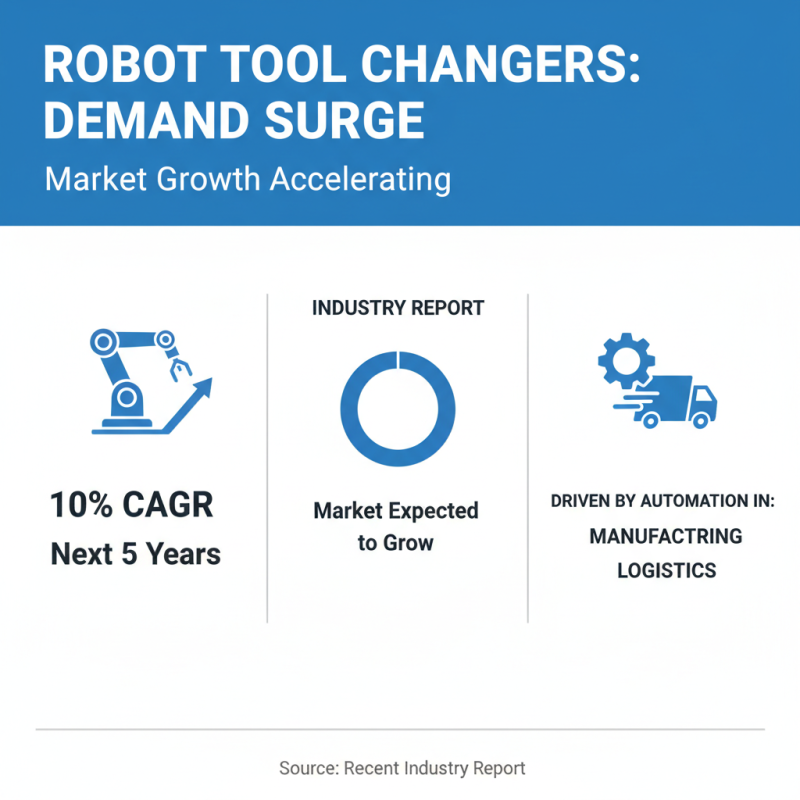

In a manufacturing facility, a leading company integrated a robot tool changer to enhance automation. The implementation aimed to decrease downtime and improve production rates. After installation, operators noted significant improvements in speed. The robot could switch tools seamlessly. However, the team faced initial challenges in aligning the system with existing workflows.

Another case involved a small assembly line. Workers struggled with repetitive tasks. They decided to adopt a tool changer to save time. The transition was not smooth. Training employees took longer than expected. Some workers were hesitant to trust the new technology. Despite these issues, the system reduced cycle times by 30%. Over time, productivity increased, leading to higher output.

Each of these cases reveals a common theme: adaptation is key. The benefits of robot tool changers are clear, yet the path to success can be rocky. Organizations must be prepared to face obstacles. Feedback from teams can guide improvements. The right mindset can make all the difference.

Impact of Robot Tool Changers on Operational Efficiency Metrics

Robot tool changers significantly enhance operational efficiency. Automation in manufacturing reached a staggering growth rate of 22% in recent years. Tool changers are essential in making systems adaptable. They allow robots to switch tools swiftly, optimizing production. Factories can see an increase in output by up to 30% with the right tool changing systems in place.

However, challenges exist. Not every tool changer fits every application. Careful consideration of compatibility is crucial. Real-time adjustments are often necessary to maintain productivity. Companies may experience downtime without proper monitoring systems. Research shows that 40% of operational delays stem from tool changeover issues.

Tips for better efficiency: Always assess your production needs before selecting tool changers. Evaluate the common tools used in your processes. Regular maintenance of tool changers can prevent unexpected failures. Small improvements in tool changing times yield substantial gains overall. Focus on training staff to handle these systems effectively.

Related Posts

-

How to Choose the Best Automatic Robot for Your Needs?

-

Top 10 Automatic Robot Innovations Transforming Our Future?

-

Top 10 Benefits of Using an Automatic Tool Changer Robot in Manufacturing

-

Top 10 Best Industrial Robots Revolutionizing Manufacturing Efficiency

-

Top Resources to Learn Robotics for Beginners and Enthusiasts?